CMD’s New 760-SUP Pouch Machine

“How

do we drive profit to our customers’ bottom line?”

That

was the question posed by CMD about four years ago when it sought to build a pouch

machine unlike anything that was currently available. After two years of

intense market research and another two years of designing, prototyping and

manufacturing, there’s the 760-SUP, a machine that’s as visually appealing as

it is high-performing. At the invitation of CMD, Flexible Packaging was able to

exclusively preview the new pouch machine at the company’s Appleton, Wisconsin,

headquarters this past summer ahead of its official PACK EXPO

introduction.

“We did a significant amount of market research to find out what the pain points were, find out what the recurring themes among converters were in terms of their user experience, the profitability of that process,” explains Scott Fuller, CMD product line manager, pouch and intermittent-motion equipment. “The pouch and bag converting process has always been looked down upon because it’s the most expensive part of the process.”

For

instance, Fuller notes it typically costs up to $70,000 to train an operator on

a new pouch machine. This takes into account both the investment in training

the employee and the loss of productivity experienced as the employee gets up

to speed. So Fuller says CMD designed the 760-SUP to shorten the average

9-month training period down to 3 and-a-half months.

“If we

can minimize that time frame and the investment they put into the operator,

that’s money right back in their pockets,” he adds.

Setup

times were another area CMD designers and engineers looked to improve. Fuller

says setups that used to take more than 2 hours are now being done in 45

minutes. Waste is another aspect that’s able to be reduced with the machine, as

any scrap is essentially money being thrown away.

In

addition to fast changeovers and less scrap, the 760-SUP is stable and

repeatable in web handling, sealing and quality; simple and intuitive; and easy

to maintain thanks to incorporated predictive maintenance technology and easy

access to system components. It’s capable of making 2-side seal, 3-side seal,

bottom gusseted and inserted gusset pouches, both with and without zipper

closures.

The 760-SUP will be exhibited for the first time at PACK EXPO. CMD is holding an official unveiling on October 14 at 10 a.m. from Booth E-7918.

CMD’s New 760-SUP Pouch Machine

Nordmeccanica to Present Industry-First Milestones, Strategic Partnerships

Nordmeccanica will focus on its recent cooperation with Henkel in an R&D project, BarrEnhanceTech Alliance. The target is to work on specific technologies relevant to improving barrier in laminated compounds for flexible packaging. The Henkel-Nordmeccanica cooperation recently generated the first commercial product, a coating to be used over AlOx metallized substrates to improve barrier while effectively protecting the metallized layer. Barrier values achievements after printing, laminating and slitting are incredible, and all technical details will be presented in detail to visitors at the Nordmeccanica booth. The product can also be used as metallization primer in regular metallization for improved metal adhesion and barrier enhancement

Nordmeccanica will also showcase the new technology developed in cooperation with Dow, an adhesive for fast curing in solventless lamination. Via the cooperation, Duplex SL One Shot, the laminator developed by Nordmeccanica, is used in combination with Symbiex, a two-component adhesive patented by Dow.

The company will also highlight the industry-first application of pattern metallization in register to an existing print and its cooperation with SEI Laser to incorporate laser die cutting on a solventless laminator.

Nordmeccanica Duplex SL One Shot

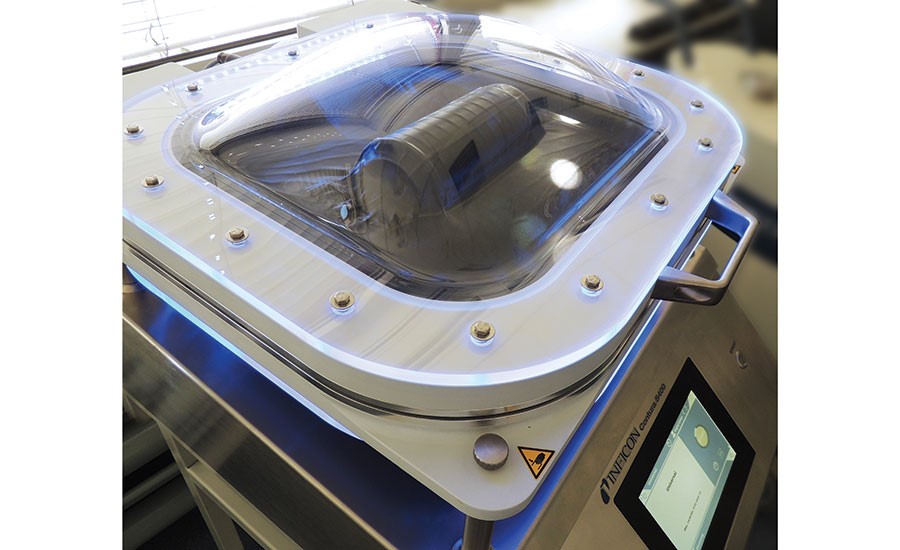

INFICON to Introduce New Leak Detector to the North American Market

INFICON is introducing and showcasing the Contura S400 leak detector for Modified Atmosphere Packaging (MAP) and flexible packages at PACK EXPO. The show will mark the leak detector’s North American packaging market debut.

Already commercialized in Europe, the Contura S400 offers a faster, easier, quantifiable and more cost-effective alternative to water baths and gas-based testing. It detects both gross and fine leaks quickly and reliably, avoiding the need for two separate machines. In addition, the system does not use test gas and eliminates the damage to packaging that can often occur with other leak detection methods. The Contura S400 is ideal for a variety of dry food applications including coffee, meat, poultry, baked goods, snack foods, confectionery/candy, cheese, grains and cereals, prepared food and produce.

“Leaks in MAP and flexible packaging are typically detected in sealed seams and downgauged packaging materials,” says Bill Burnard, vacuum control sales and business development manager – North America. “The Contura S400 relies on a proprietary differential pressure method to identify leaks, both large and small. This unique, non-destructive approach allows dry food manufacturers to efficiently and accurately determine if hermetically sealed packages are airtight before they ever reach the market.”

INFICON’s Contura S400

Mondi’s New Packaging Laminate

Mondi will exhibit its new BarrierPack Recyclable packaging laminate, which can help reduce plastic packaging waste through recycling. This plastic laminate for pre-made pouches and FFS roll-stock is fully recyclable without any compromise of quality or functionality.

“At Mondi, we work towards a circular economy and these recyclable packaging solutions are good examples of how we will change the conversation about plastic packaging through continued R&D and partnership,” says Sara Sizer, Mondi’s communication and marketing director.

Mondi will exhibit its new BarrierPack Recyclable

W&H Subsidiary to Demonstrate Flat and Gusseted Bag Making

Garant, a member of the W&H Group, will have a machine on hand running flat and gusseted bags. W&H will also discuss its new joint venture, Aventus, which it recently formed with Haver & Boecker to specialize in discovering new solutions in everything from packaging free-flowing loose goods to finished pallets.

Toray Advances Trio of Packaging Film Lines

Toray Plastics (America), Inc., will feature advancements in three families of its packaging films: Torayfan clear barrier BOPP, Torayfan white BOPP and Lumirror high barrier PET. These portfolios are manufactured with Toray’s proprietary technology and provide CPG companies and converters with creative solutions that deliver robust performance with a lower total cost.

Toray’s Torayfan CB3 portfolio is a new generation of transparent high-barrier BOPP films. CB3 films are available in 70 and 80 gauges in sealable and non-sealable versions. These new films are PVdC-free and offer superior barrier-durability protection for nuts, seeds, snacks, cookies, dried fruit and confections.

The new Torayfan white pigmented BOPP films for snack food packaging are metallized on one side in sealable and non-sealable versions, and are available in a variety of barrier levels and heat-seal strengths. Toray’s white films combine the pigment, sealant and barrier in one web, enabling the manufacture of a standard two-ply lamination.

Toray’s new Lumirror high-barrier PET films are designed to provide extended shelf life. The new MK6HB metallized film offers ideal oxygen and moisture-barrier protection, and PA1HB is a clear-barrier film that delivers outstanding oxygen barrier. Both offer superior aroma protection.

Mamata to Hold Live Demonstration of PFS Series Machines

Mamata will conduct live demonstrations of its PFS Series Pick-Fill-Seal machine for packaging pre-formed pouches. The machine is specifically designed to deliver 95 percent efficiency thanks to its uniquely-designed pouch feeding system, and patented bag clamp and transportation system. Mamata’s live demonstrations of the machine will also showcase its fast changeover times of less than 20 minutes.

Vegapack PFS-Series

Pearl Showcasing New Large Sized Cross Rail Ball and Die Unit

Pearl is championing the availability of its Large Sized Cross Rail Ball and Die Unit. Like its smaller counterparts, this attachment allows for hole punching in the middle of continuous motion webs. The two-piece split punch and die system (top and bottom halves) allows the web to pass in-between, while the sure alignment structure guarantees that punches are centered over the dies. The new D-Size unit has a maximum punch size of 2.25 inches in diameter.

“Pearl’s customers asked for larger ball and die options to accommodate their converting applications,” says Nik Green, senior R&D manufacturing engineer at Pearl. “So we scaled up the unit and tested it in our R&D Application Lab. We can now say that we offer another solution for converters who are looking for larger hole applications.”

Pearl’s attachment offers adjustable height to allow for die re-sharpening. The clean, high quality holes are great for drawstring bags, agricultural films or any other flexible packaging requirement. A vibration dampening carriage reduces noise. Additional options include a venturi unit for slug removal or electrical controller to accommodate varying patterns as well as speeds.

Pearl’s Large Sized Cross Rail Ball and Die Unit